SIRUITE DRILLING TOOLS LIMITED

SIRUITE DRILLING TOOLS LIMITED

SIRUITE DRILLING TOOLS LIMITED

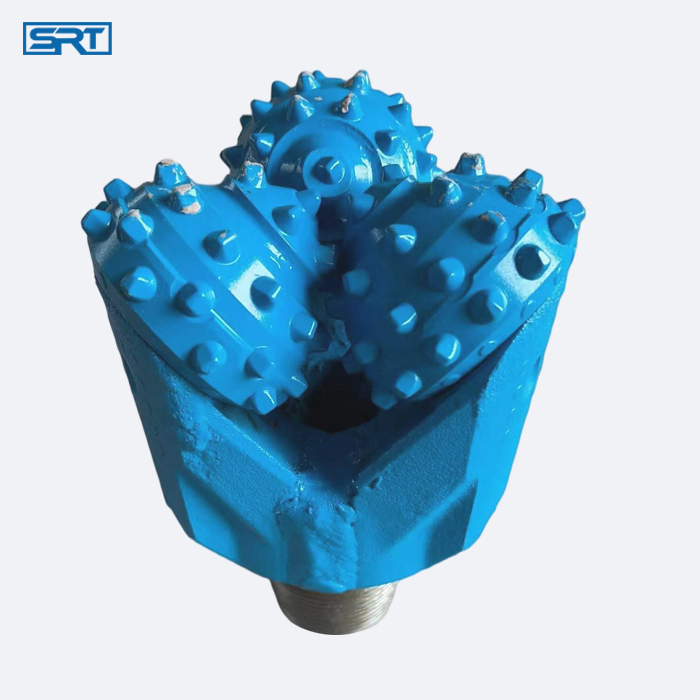

Roller Cone Bits are equipped with conical cutters or cones, adorned with either steel teeth or tungsten carbide buttons. When the drilling string is set in motion, these cones move in a cyclical manner across the borehole base. As this movement persists, fresh teeth touch the hole's base, fragmenting the surrounding formation. Drilling fluid or air then uplifts the fragmented rock particles from the hole's depth, moving them up the annulus. With the ongoing rotation, subsequent teeth reach and interact with the borehole's base, producing more fragments. To ensure resilience against extreme heat and long operational durations while drilling, it's essential that both Premium tungsten carbide insert (TCI) bits and milled tooth (MT) bits be meticulously crafted. They should be robust enough to penetrate formations ranging from soft to extremely hard.

Advantages & Disadvantages

(1) Versatile (2) intial cost is low(3)more control options (4)better in varied and complicated rock formation,especailly in hard (5)more impact resistance(6)Slow (7)possibility to loss cone(8)Short service life

A significant benefit of tricone bits is their longstanding history in the industry. This extended period has facilitated the progressive refinement and production of tricone bits, integrating developments in materials like Tungsten Carbide Inserts and innovations in design, such as encapsulated journal bearings.

In challenging conditions, tricone bits offer improved manageability, granting a broader spectrum of adjustments for torque and Weight On Bit.

Furthermore, tricone bits excel in handling a spectrum of geological terrains, notably the tougher ones. The movement of each roller on the tricone bit contributes to breaking down the rock, enhancing its adaptability to various earth formations.

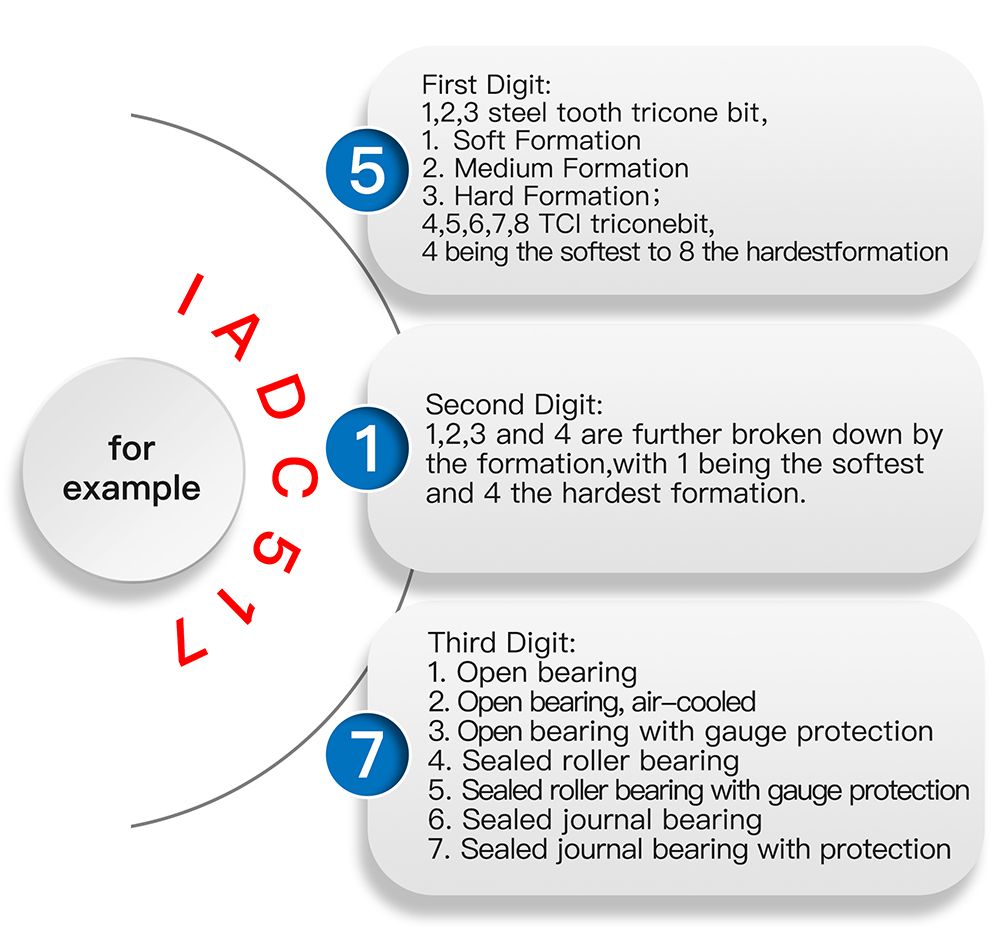

IADC CODE